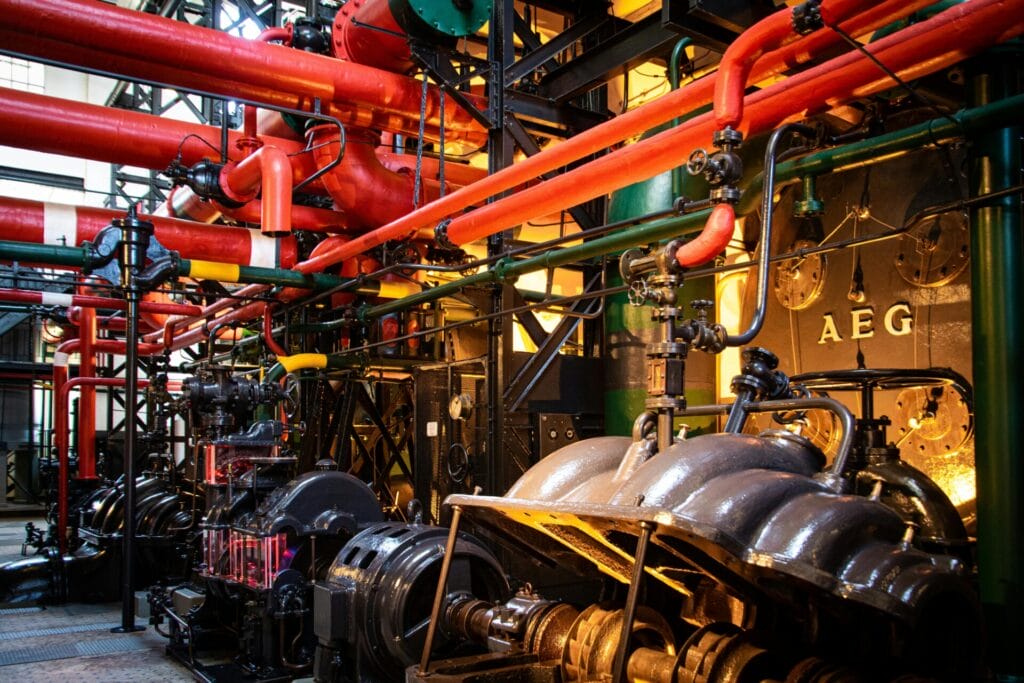

In the intricate world of offshore operations, where efficiency and reliability are paramount, the concept of spare parts management holds immense significance. At Kent Offshore, we understand the pivotal role that spare parts play in ensuring uninterrupted operations and minimising downtime. In this blog, we delve into the fundamentals of spare parts management and why it’s crucial for the smooth functioning of offshore ventures.

The Basics of Spare Parts Management

Spare parts management involves the systematic planning, procurement, storage, and utilisation of spare parts to support ongoing operations. These parts serve as backups for critical equipment and machinery, ensuring that any unexpected failures or breakdowns can be swiftly addressed without disrupting operations.

Importance in Offshore Operations

In the offshore industry, where equipment is subjected to harsh environmental conditions and rigorous usage, the need for effective spare parts management is even more pronounced. Offshore platforms and vessels rely on a myriad of complex machinery and systems, each comprising numerous components that are susceptible to wear and tear.

Key Components of Spare Parts Management

- Inventory Optimisation: One of the primary objectives of spare parts management is to strike the right balance between having adequate inventory to meet demand while avoiding excessive stockpiling that ties up capital and storage space. Advanced forecasting techniques and inventory optimisation tools help streamline inventory levels and ensure optimal availability of critical spare parts.

- Supplier Management: Establishing reliable relationships with trusted suppliers is essential for timely procurement of spare parts. Working closely with suppliers ensures access to genuine parts, competitive pricing, and efficient delivery processes, thereby minimising lead times and enhancing operational resilience.

- Storage and Warehousing: Proper storage and warehousing facilities are crucial for preserving the integrity of spare parts. Offshore environments present unique challenges, including exposure to saltwater, humidity, and temperature fluctuations. Implementing appropriate storage solutions, such as climate-controlled warehouses and corrosion-resistant packaging, safeguards spare parts against deterioration and extends their lifespan.

- Maintenance Planning: Integrating spare parts management with maintenance planning is essential for proactive asset management. By analysing equipment reliability data and historical failure patterns, maintenance schedules can be optimised to coincide with the availability of critical spare parts, thereby minimising downtime and maximising asset uptime.

- Lifecycle Management: Adopting a lifecycle approach to spare parts management involves evaluating the lifecycle costs of equipment and aligning spare parts strategies accordingly. This includes identifying obsolete parts, implementing obsolescence management plans, and investing in alternative solutions such as reverse engineering or 3D printing to ensure continued availability of essential components.

Conclusion

In the dynamic and demanding environment of offshore operations, spare parts management emerges as a linchpin for operational continuity and asset reliability. By adopting a strategic and systematic approach to spare parts management, organisations can mitigate risks, enhance operational efficiency, and ultimately achieve sustainable success in the offshore industry.

At Kent Offshore, we recognise the critical importance of spare parts management in supporting our clients’ operations. With our expertise in procurement, logistics, and asset management, we stand ready to partner with offshore ventures in optimising their spare parts strategies and maximising operational resilience. Contact us today to learn more about our comprehensive solutions tailored to the unique needs of the offshore industry.